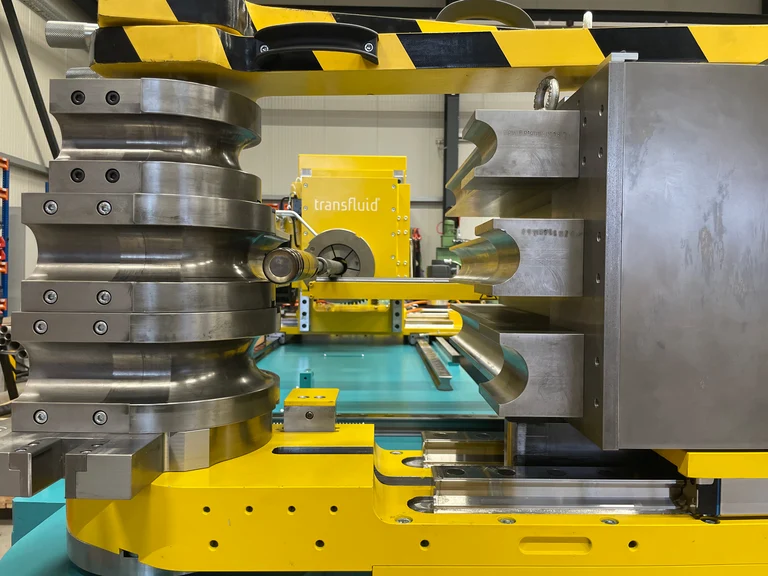

t bend - Mandrel bending machines

with servo-hydraulic motors for guaranteed

extraordinary bending quality.

Energy savings up to 70% by control of the hydraulic pump via a servo motor.

Typical bend time for a 4-bend wall rail is less than 2 minutes

Bends steel, stainless steel and aluminum

Bends to the same radius as purchased elbows, so when an elbow is still required, the bends look exactly the same

Accuracy and repeatability allow for the rail to be used as a template, greatly reducing layout time on the bench

Explore our machine virtually

Move the slider and click the info points for more information.

The right machine for your task

MANDREL BENDING MACHINES Hydraulic with CNC-Control

| Range | 1/4" - 1 5/8" |

| Max. capacity | 1 5/8" x .157" (mild steel) 1 5/8" x .120" (stainless steel) 1" x .1" (square mild steel) |

| Max. Radii | 5" |

| Usable length | 15 ft 20 ft (special) |

| Speed of bending axis | 75 °/sec. |

| Range | 1/4" - 2 3/8" |

| Max. capacity | 2 3/8 x 3/16"mm (mild steel) 2 3/8 x 1/8" mm (stainless steel) on request (square mild steel) |

| Max. Radii | 7 1/16" |

| Usable length | 15 ft 20 ft (special) |

| Speed of bending axis | 35 °/sec. |

| Range | 1/4" - 3 1/2" |

| Max. capacity | 3 1/2" x .188" (mild steel) 3 1/2" x .120" (stainless steel) on request (square mild steel) |

| Max. Radii | 10.6" |

| Usable length | 15 ft (standard) 20 ft (special) |

| Speed of bending axis | 21°/sec. |

| Range | 3/4" - 5" |

| Max. capacity | 4 1/2" x .177" (mild steel) 4 1/2" x .125" (stainless steel) on request (square mild steel) |

| Max. Radii | 14.2" |

| Usable length | 20 ft (standard) |

| Speed of bending axis | 15 °/sec. |

| Range | 1 1/2" - 5.1/2" |

| Max. capacity | 5 1/2" x .236" (mild steel) 5 1/2" x .157" (stainless steel) on request (square mild steel) |

| Max. Radii | 16.5" |

| Usable length | 20 ft (standard) |

| Speed of bending axis | 10 °/sec. |

| Range | 1 5/8 - 6 3/4" |

| Max. capacity | 6 3/4 x 5/16" (mild steel) 6 3/4 x 1/4" (stainless steel) on request (square mild steel) |

| Max. Radii | 20" |

| Usable length | 20 ft (standard) |

| Speed of bending axis | 7 °/sec. |

| Range | 1 1/2" - 6 5/8" |

| Max. capacity | 6 5/8" x .315" (mild steel) 6 5/8" x .236" (stainless steel) on request (square mild steel) |

| Max. Radii | 20" |

| Usable length | 20 ft (standard) |

| Speed of bending axis | 7 °/sec. |

| Range | 2 3/8" - 10 1/2" |

| Max. capacity | 10 1/2" x .630" (mild steel) 10 1/2" x .551" (stainless steel) on request (square mild steel) |

| Max. Radii | 32.3" |

| Usable length | 20 ft |

| Speed of bending axis | 3 °/sec. |

| Range | 3 1/8" - 12 3/4" |

| Max. capacity | 12 3/4" x .787" (mild steel) 12 3/4" x .709" (stainless steel) on request (square mild steel) |

| Max. Radii | 38.4" |

| Usable length | 20 ft |

| Speed of bending axis | 3 °/sec. |

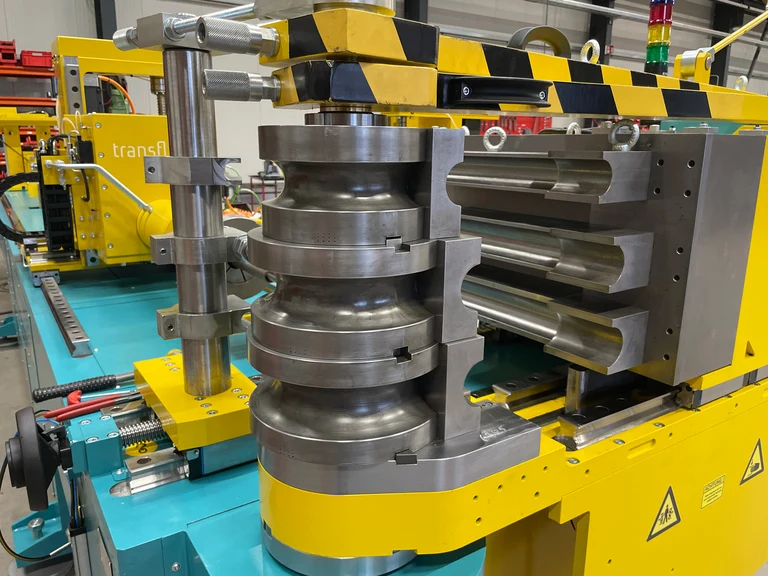

INNOVATIVE SERVO-HYDRAULIC SYSTEM

• Energy savings up to 70% by control of the hydraulic pump via a servo motor.

• On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components.

• Speed and volume of the pump can be precisely adjusted as required.

• Pressure is programmable and stored with program, eliminating operator intervention.

• Heating of the oil eliminated, therefore no additional cooling unit for the oil is necessary.

• The pumps and motors can be specified to a smaller size precisely for the application, which increases efficiency.

Catalog Download

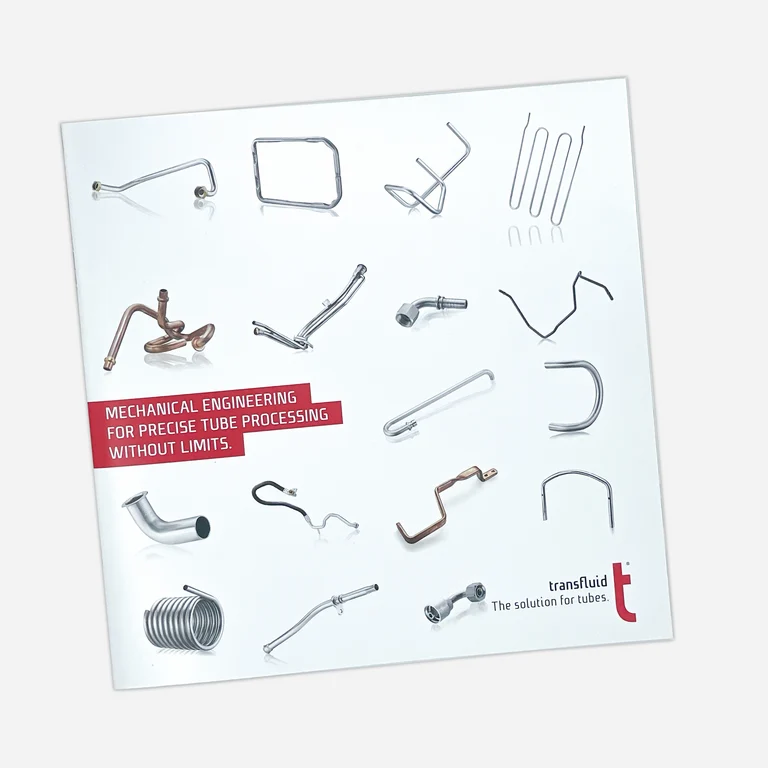

transfluid® offers the complete package for the production of tubing.

Download our new catalogue.